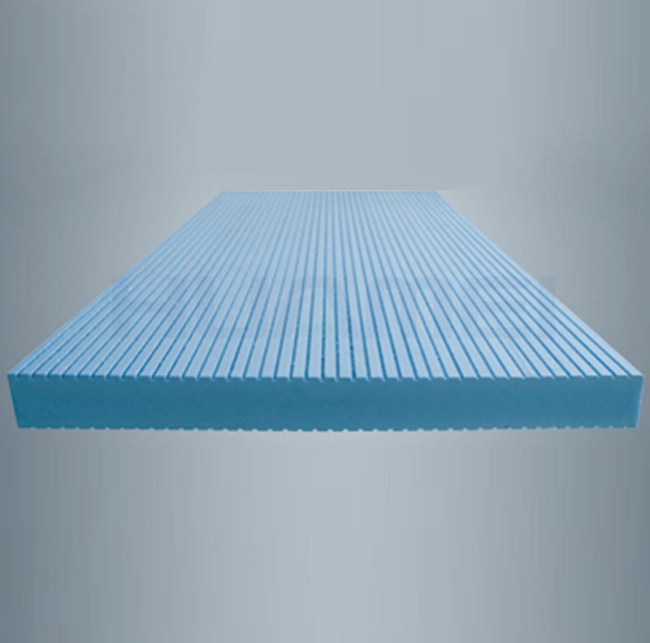

Extruded plate (XPS), based on polystyrene resin as raw material, through a special process of continuous extrusion foaming molding hardboard, its internal structure for independent closed bubbles, is one kind has high pressure, water absorption, moisture, breathable, lightweight, corrosion resistance, long service life, low coefficient of thermal conductivity, excellent environmental protection heat preservation material performance. Extruded polystyrene (XPS) insulation board is widely used in wall insulation, flat concrete roof, and steel structure roof insulation, low-temperature storage ground, parking platform, airport runway, highway and other fields of moisture-proof insulation, and control ground frost heave.

1. Excellent and long-lasting thermal insulation

The extruded board has a thermal conductivity of 0.028w/MK, which has the characteristics of high thermal resistance and low linear expansion rate. Its thermal conductivity is far lower than other insulation materials such as EPS board, foamed polyurethane, insulation mortar, cement perlite, etc. At the same time, because the material has a stable chemical structure and physical structure, it ensures the durability and stability of the material's thermal insulation performance.

2. Superior water resistance and moisture resistance

The extruded board has a tight closed-cell structure. The molecular structure of polystyrene itself does not absorb water, and there are no gaps on the front and back of the board. Therefore, the water absorption rate is low, and the moisture and penetration resistance is good.

3. High-strength compression resistance

Because the foam structure is closely connected and there is no gap between the walls, the extruded board has high compressive strength, and the blisters remain unchanged even for a long time. Therefore, it can be used for parking platforms, airport runways, highways, and other fields with good impact resistance.

4. Anti-corrosion, durable

General rigid foam insulation materials are prone to aging after a few years of use, which will result in water absorption and performance degradation. The extruded board has excellent anti-corrosion, anti-aging, and heat preservation properties, and can still maintain its excellent performance under high water vapor pressure, and the service life can reach 30-40 years.

5. Lightweight, high hardness

The fully closed-cell foamed structure of the extruded board is lightweight, and the uniform honeycomb structure results in high rigidity, but it is not as brittle as polyurethane foam and phenolic foam, so it is not easy to be damaged. It is not only easy to handle and install, but also to cut Easy, it will not affect the bearing capacity of the structure when used as roof insulation.

Six, high-quality environmental protection type

The extruded board will not decompose and mildew, will not volatilize harmful substances and have stable chemical properties. At the same time, in the production process, environmentally friendly raw materials are used, no harmful gas is generated, no wastewater is generated, and the formed solid waste can be recycled and reused. It is a high-quality environmentally friendly product.

It can be seen that as a floor heating insulation material, the performance of the extruded board is better than that of polystyrene foam board, but the price is higher.

The above information is provided by the boat rubber foam factory.

评论

发表评论