In the insulation of air-conditioning ducts and the insulation of buildings, both rubber insulation cotton and glass wool can play a certain role in insulation, and both have similar performance. Because both have the advantages of energy-saving, convenient installation, labor cost-saving, and labor intensity reduction, they have good economic and social benefits and play an important role in creating an effective, energy-saving, comfortable and safe working environment and home environment.

1. Different appearance

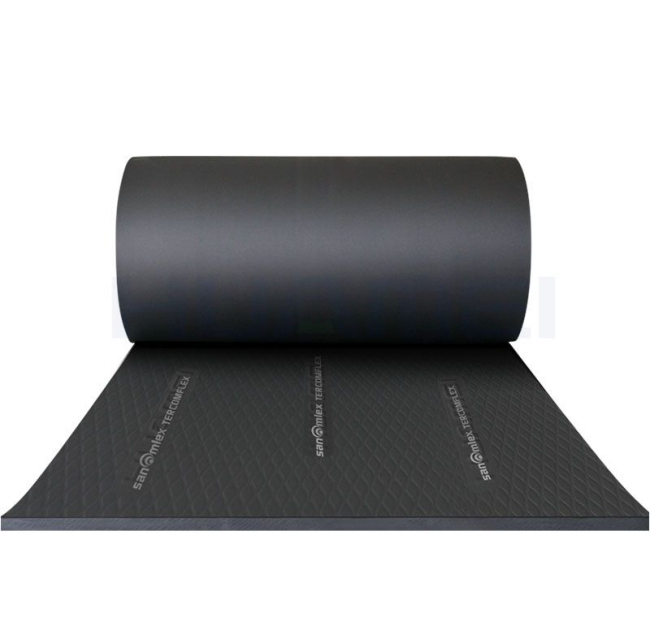

Rubber and plastic insulation materials are made of effective foam, soft and tough. It occupies very little space during the installation process, so it occupies very little space after completion and looks very beautiful after installation. The glass wool has an open-pore structure and is a hard inorganic material. During the installation process, it will take up a lot of space, especially the height of the ceiling will be affected, and it is not easy to form after installation.

2. Different thermal conductivity

The initial thermal conductivity of rubber-plastic thermal insulation material is 0.035W/(m·k), and the initial thermal conductivity of glass wool is 0.038W/(m·k). The lower the λ value of the thermal conductivity, the better the thermal insulation effect of the material. Through comparison, it can be seen that the insulation performance of rubber and plastic insulation materials is significantly better than that of glass wool.

3. Different flame retardancy

The flame retardancy of rubber and plastic insulation materials is usually B1 or B2, and the flame retardancy of high-grade rubber and plastic insulation materials is B1 flame-retardant material. The material meets national standards and can effectively prevent fires. The flame retardancy of glass wool is Class A, and the flame retardancy and fire resistance are inferior compared with rubber and plastic insulation materials.

4. The construction progress is different

The density of rubber-plastic insulation material is higher than that of glass fiber, but rubber-plastic insulation material is relatively soft, which is more convenient and quick in actual construction and operation. In future use, it is not easily damaged and easy to repair. In the installation process, the glass wool needs three steps of cutting, bonding, and binding, which is not easy to operate.

5. Different economic performance

Rubber and plastic thermal insulation materials are usually used for the insulation treatment of air conditioners and buildings. Although the unit price is slightly higher, its auxiliary materials have low cost, low loss, long service life, and low annual cost. Glass wool is mainly used for sound absorption and sound insulation in large places such as stadiums and workshops, and its material unit price is slightly lower. However, due to poor waterproof performance, an additional fireproof layer is required.

The above information is provided by the rubber foam insulation factory.

评论

发表评论