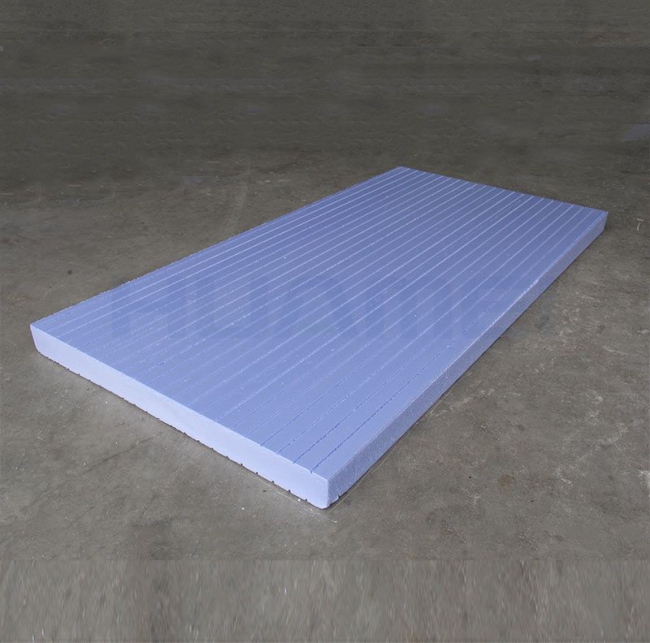

The full name of the extruded board is extruded polystyrene foam board or extruded board for short, also known as XPS board. It is a material that is continuously extruded and foamed through a special process. The hard film formed on the surface is uniform, the inner closed-cell foams continuously and uniformly, and the honeycomb structure is formed. It has high compression, lightweight, no water absorption, air permeability, and resistance features such as abrasiveness and non-degradation.

It is especially suitable for heat insulation, heat preservation, and moisture-proof treatment of buildings. Through positioning, the overall size of the template and the front and rear distance of the section can be adjusted to adjust the layout width, and then the positioning alignment can be adjusted to adjust the width of the card.

1. Thermal insulation

The sealing rate of the extruded board structure is greater than 99%. The vacuum layer is formed to avoid airflow and heat dissipation to ensure the durability and stability of its thermal insulation performance. The sealing rate of foamed polyurethane is only 80%, which proves that 20mm The thermal insulation effect of thick XPS extruded thermal insulation board is equivalent to that of 50mm thick expanded polystyrene and 120mm thick cement perlite, which is currently the first choice for building thermal insulation.

2. Hydrophobic and moisture-proof

After the thermal insulation material absorbs water, the thermal insulation performance decreases. The inhaled water is easy to freeze at low temperatures, which destroys the structure of the thermal insulation material and reduces the compression and thermal insulation performance of the thermal insulation board. However, because the molecular structure of polystyrene itself does not absorb water, the molecular structure of the board is stable. There is no gap, which solves the problems of leakage, penetration, freezing, and condensation of other materials.

3. Has high compressive strength

Due to the special structure of the extruded board, its compressive strength is very high and its impact resistance is very strong. The compressive strength is above 150~500kpa, can withstand the ground load of various systems, and is widely used in geothermal engineering, highways, airport runways, square floors, large-scale cold storage, automobile interior decoration, and insulation, and other fields.

4. Has good stability and corrosion resistance

The chemical properties of the extruded board are extremely stable and will not age, decompose, or produce harmful substances when used for a long time. Even after 30 years of use, it can still maintain excellent performance, will not rot, mold, and will not volatilize toxic substances.

5. Reliable

The closed-cell foaming chemical structure and its honeycomb physical structure is light in texture and easy to use. It has the characteristics of high strength, easy to cut and transport, not easy to damage and install.

6. Product environmental performance

The extruded board has been inspected by relevant national departments, and its chemical properties are stable, non-volatile harmful substances, and harmless to the human body. The raw materials produced are environmentally friendly materials and do not produce any industrial pollution. It is an environmentally friendly building material.

The above information is provided by colorful rubber foam supplier.

评论

发表评论