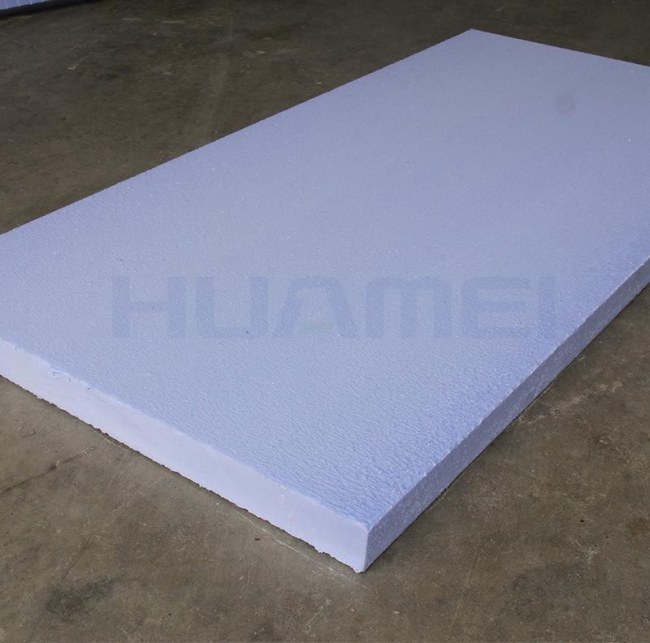

The polymer foaming material is a gas-solid two-phase composite material composed of polymer and gas molecules. It can have bubbles as the dispersed phase, polymer as the continuous phase, or both. The extruded board is a kind of polymer foam material.

Polymeric foam materials can be divided into high, medium, and low density, open cell and closed cell, hard and soft, physical foam, chemical foam or free foam, Structural foaming can also be divided into thermoplastic and thermosetting foamed materials.

When a large number of extruded panels purchased at the construction site are not in use temporarily, they need to be stored and can be used directly when needed. The storage method of the extruded board is very important, so what are the precautions for preserving extruded board?

Prohibition of fire: No matter whether the extruded board is placed indoors or outdoors, any kind of fire should be prohibited. No flammable and explosive dangerous goods should be placed around it. At the construction site, the extruded board should be kept away from electric welding, grinding wheel cutting, and other construction operations. When performing electric welding, grinding wheel cutting operations, etc., fire-resistant materials should be used to separate the extruded board from the welding tools to prevent sparks from splashing on the extruded board.

No heavy pressure: After the extruded boards are stacked on the construction site, do not place heavy objects on them to avoid damage and crushing of the extruded boards. In addition, the height of the stack of materials should also be limited. If it is too high, the weight will increase. The bottom material is easily crushed and damaged, and it is also easy to tilt and fall, posing a threat to safety.

Keep ventilation: When the extruded board is stored indoors, you need to pay attention to ventilation. In this way, the turbid air in the room can be discharged in time to ensure the convection of the air in the room, and it can also prevent the accumulation of fine floating objects such as dust and particles in the room from causing an explosion and threatening the lives of construction workers.

Keep away from anti-corrosion materials: In the storage process, the extruded board should not be exposed for a long time or contact with some more corrosive substances, dust or other corrosive materials.

The above information is provided by the extruded board supplier.

评论

发表评论