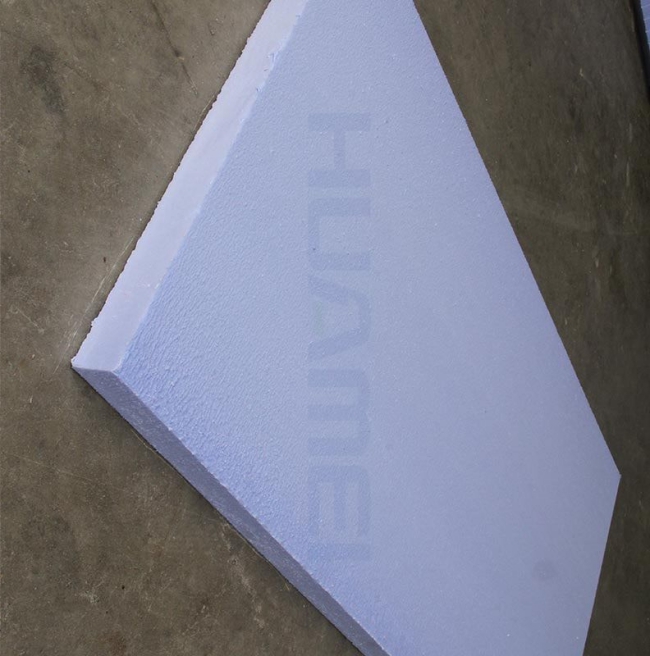

XPS extruded board has the good waterproof and moisture-proof performance. Everyone knows that warehouses are used to store things and need to be moisture-proof. So what are the advantages of extruded boards for moisture-proof storage in warehouses?

As we all know, the items stored in the warehouse must not be damp, otherwise the use-value of the product will be seriously affected, or even scrapped. To ensure a dry environment in the warehouse and reduce quality problems during storage, it is necessary to surround the warehouse with moisture-proof sheets to form a protective layer so that external factors will not cause any impact on it.

Water absorption. Install the extruded board on the outer wall of the warehouse. Even in the rainy season, it is difficult to break through the line of defense of the board. A protective layer prevents rainwater from affecting the products in the warehouse. This is because the board has good water absorption and slows down as the temperature gradually rises. Slowly evaporate, no residues will occur, and the whole use effect will be long-lasting, which will greatly protect the warehouse and control leakage.

It is worth noting that under low-temperature conditions, the protection of the extruded board can still be effective and will not cause moisture problems.

The extruded board is quite superior in terms of waterproof and moisture-proof, which can fully restrain the influence of external factors and ensure that the entire warehouse is not damaged.

What is the anti-corrosion effect of the XPS extruded board?

XPS extruded board has the characteristics of non-aging, non-decomposition, and no harmful substances during long-term use. Its chemical properties are very stable, and it will not be degraded due to water absorption and corrosion, which will cause its performance to decline. It will still be in a high-temperature environment and can maintain superior performance.

According to relevant data, XPS extruded insulation board can still maintain excellent performance even after 30-40 years of use, and there will be no decomposition or mildew, and there will be no volatilization of toxic substances. In terms of environmental performance, the XPS extruded board has been tested by the national quality department, and its chemical properties are stable non-volatile harmful substances, and harmless to humans. The production of raw materials is environmentally friendly materials and will not cause industrial pollution. This shows that the extruded board is a truly environmentally friendly building material.

To sum up, the XPS extruded board not only has good corrosion resistance and stability but also is very environmentally friendly, which is very popular for people with increasingly strong environmental awareness.

The information is provided by construction rubber foam supplier.

评论

发表评论