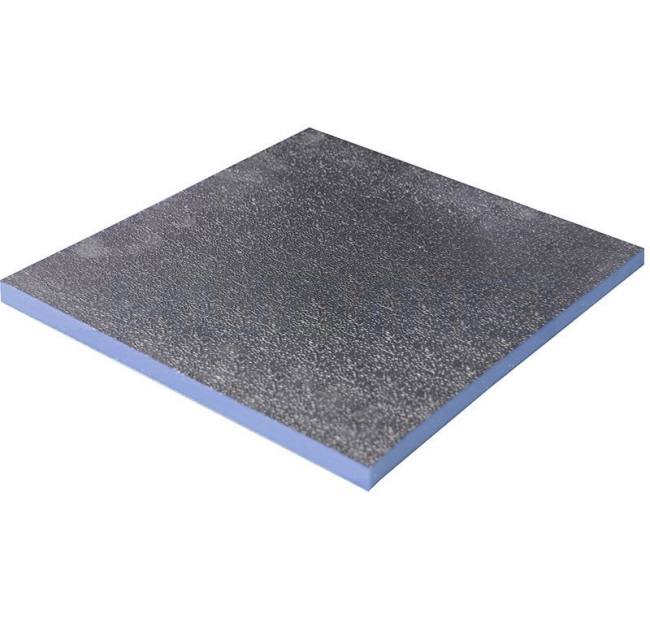

The extruded board has good heat preservation and compression performance, and its moisture-proof and anti-corrosion performance is also very good. It mainly plays the role of heat preservation and heat insulation and is used in building roofs, building grounds, and high-speed railway subgrades. A good extruded board is not only of good quality but also meets the customer's requirements. So what issues should be paid attention to when choosing an extruded board?

1. It is necessary to clarify the size and model of the extruded board to be purchased.

2. You must be clear about the quantity you need to buy and don't buy some extruded boards of inferior quality for cheap.

3. When buying, look at the appearance and color. There are extruded boards in many colors on the market. Please pay attention to choosing a board with a smooth and delicate appearance and pure color.

4. We need to buy extruded boards with uniform surface layer and cells. The more uniform the cells, the better the quality. Try not to choose gray extruded boards.

5. You can press the extruded board with your hand when you buy it. The good extruded board will not be seen after pressing, and the poor quality extruded board will have obvious dents.

6. When the flame-retardant extruded board is burned with fire, the flame will burn when it is close to the extruded board, and the flame will go out automatically when it leaves it. However, poor quality boards will keep burning.

Before purchasing extruded panels, we need to find a trustworthy extruded panel manufacturer for long-term cooperation, so how to choose a good extruded panel supplier? It can be measured from the following points.

1. The production scale of the enterprise. Don’t think that your purchase volume is not large, so choose to go to a small-scale workshop to place an order for purchase. Only large-scale manufacturers will have advanced flow-type production lines, and the processing process is professionally based on standards. Completed by the fully automatic machine, all the moulding procedures are directly completed by the mechanical operation. Small factories are basically manual set mold, precision is not high, and may even be recycled material reprocessing. Most of the extruded boards produced are substandard products, and even the quality of the products is very poor, which can not play the performance of the extruded board. However, the quality of extruded panels produced by the superior regular extruded panel manufacturers is smooth, flat, non-marking, and high in the pass rate. Such products are excellent products, so the production scale of the company is a very important criterion.

2. The reputation of the company, the quality of the basic products of a good company is also guaranteed, and it can be investigated clearly before formal cooperation. Whether the manufacturer has obtained industry qualification certificates can be used as a reference. Extruded plate manufacturers with more complete qualifications are often more reliable.

评论

发表评论