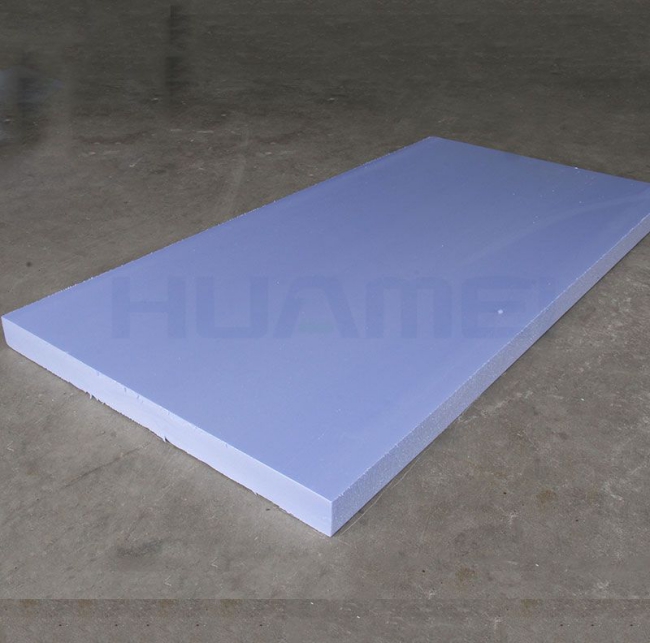

XPS extruded board is made of polystyrene resin or its copolymer as the main component, adding a small number of additives, and made by heating and extruding rigid foam products with closed-cell structure. XPS extruded board can stand out among many thermal insulation materials, and it must have its own advantages. Let's take a look together:

1. Thermal insulation

XPS board has the characteristics of high thermal resistance, low linearity, and low expansion ratio. It is precise because of this structural feature that the closed cell rate is as high as 99%, and a vacuum layer can be formed inside, which greatly avoids heat dissipation caused by air circulation, and ensures long-term effectiveness and stability of heat preservation.

2. Compression resistance

Due to the special structure of the XPS board, it has high compressive strength and strong impact resistance. Depending on the type and thickness of the XPS board, its compressive strength is as high as 150-500KPA and can basically withstand the load of various systems. Therefore, it is widely used in fields such as geothermal parks, airport runways, highways, and car interior decoration, and insulation.

3. Waterproof and moisture-proof

The water absorption rate of the XPS board is extremely low and will decrease with the decline of heat preservation performance. In the case of low temperature, the non-absorbent property prevents water from penetrating into the interior, which well protects the internal structure of the insulation material. Therefore, the XPS board can cope with extreme weather problems, and solve the problems of water leakage, penetration, and icing lights.

4. Light texture

The XPS board USES a fully closed foamed structure, similar to a honeycomb structure. Therefore, it has the characteristics of ultra-lightweight and high strength. No matter in construction or transportation, it is not easy to be damaged, high efficiency in cutting, no delay, and very convenient in installation and operation, which is favored by many projects.

The above information is provided by construction rubber foam supplier.

评论

发表评论